DIY workbench plans: build your perfect workspace with ease

DIY workbench plans enable you to create a functional workspace tailored to your needs, focusing on materials, construction stability, customization, and maintenance for lasting performance.

If you’re looking to create your own workspace, DIY workbench plans can help turn your vision into reality. Whether you’re a seasoned DIY enthusiast or just starting out, having a custom workbench allows you to tackle projects with confidence. Let’s delve into how you can design and build the perfect workbench for your needs.

Understanding the basics of DIY workbench plans

Understanding the basics of DIY workbench plans starts with recognizing why having a workbench is essential. A well-designed workbench provides a sturdy surface for various projects, whether you’re woodworking, crafting, or performing repairs.

Before diving into specific plans, consider the dimensions of your workbench. Think about the space available in your workshop or garage. A standard height is around 36 inches, but adjust it based on your comfort and the type of work you’ll be doing.

Next, identify the materials you want to use. Common choices include plywood, MDF (medium-density fiberboard), or solid wood. Each material has its benefits. For instance, plywood is cost-effective and versatile.

Another critical factor is the storage options. Incorporating shelves, drawers, or pegboards into your design can help keep tools organized and accessible. Think about what tools you use frequently and how best to store them.

In addition to storage, consider any additional features you might want. Do you need built-in clamps? Maybe a power strip for easy access to electricity? These elements can greatly enhance the functionality of your workbench.

Lastly, don’t forget to review workbench designs that suit your needs. There are countless templates and styles available online, ranging from simple to complex. Choose a plan that aligns with your skills and the tools available.

Choosing the right materials for your workbench

Choosing the right materials for your workbench is crucial for ensuring its durability and functionality. Start by considering plywood, which is popular for DIY projects. It is affordable, lightweight, and sturdy. For a smooth working surface, you might opt for cabinet-grade plywood or hardwood layers.

Medium-density fiberboard (MDF) is another excellent option. It provides a smooth surface perfect for tasks that require precision. MDF is easy to work with, and it’s ideal for painting and finishing.

If you prefer a more robust surface, consider using solid hardwood, such as maple or oak. These materials offer excellent resistance to wear and tear and can last for generations. However, they tend to be more expensive.

Don’t forget about the frame of your workbench. Using 2×4 lumber for the legs and supports can create a strong foundation. It’s essential to build a sturdy frame that will hold up under heavy loads.

When selecting materials, also think about finishing. A good finish, like polyurethane or varnish, will protect your workbench from spills and wear while allowing easier cleaning.

Lastly, consider sustainability. If you want to use recycled or reclaimed wood, make sure it’s free from pests and in good condition to ensure safety and longevity.

Essential tools needed for DIY workbench construction

When building your own DIY workbench, having the right tools is essential for a successful construction process. Start with a measuring tape, which is crucial for ensuring accuracy in your measurements.

Next, a circular saw will make cutting wood and other materials much easier. It enables you to make straight cuts quickly, reducing the need for manual sawing.

A drill is another vital tool. An electric drill allows you to drive screws into your workbench, securing the pieces together. A cordless drill can provide more flexibility as you move around your workspace.

Don’t forget about a screwdriver set. Having various sizes ensures that you can handle different screws and fasteners effectively. This is especially helpful for detailed work where precision is required.

For assembly, a level is important. It helps you verify that everything is even and properly aligned, which is vital for a sturdy and functional workbench.

A clamp can greatly improve your work when holding pieces of wood in place while you drill or screw them together. This ensures stability and accuracy during assembly.

Finally, consider investing in a good safety gear set, including goggles and ear protection. Safety should always come first when working with power tools.

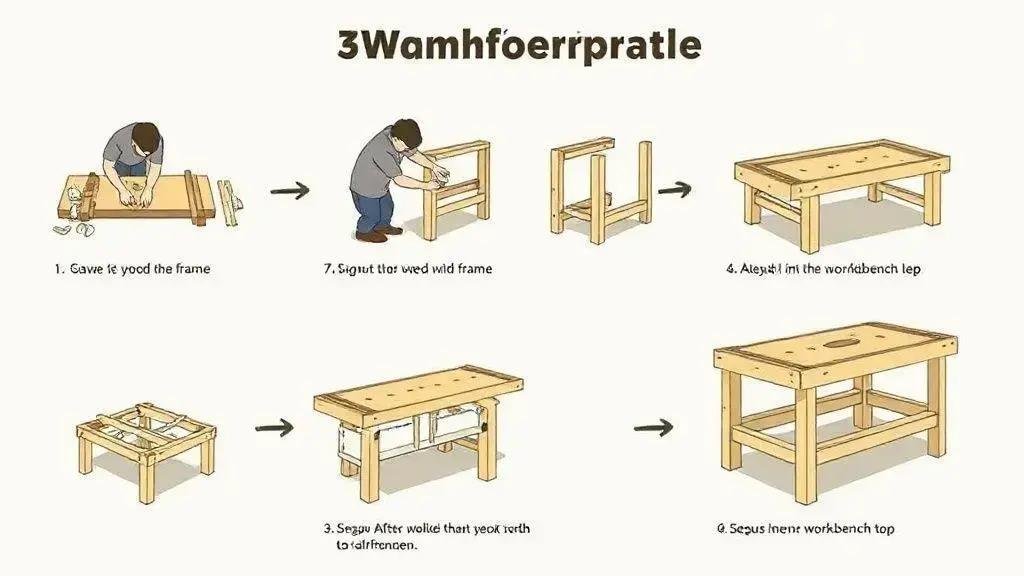

Step-by-step guide to building your workbench

Building your own workbench can be a rewarding project. Follow this step-by-step guide to create a sturdy and functional workbench.

Step 1: Gather Materials – Start by collecting all necessary materials based on your chosen plan. You’ll typically need plywood for the top, 2×4 lumber for the frame, screws, and wood glue.

Step 2: Measure and Cut – Use your measuring tape to determine the dimensions for the top and frame. Cut the plywood and lumber accordingly with your circular saw. Double-check measurements to ensure everything fits well.

Step 3: Assemble the Frame – Begin by assembling the frame using the 2×4 lumber. Use wood screws to secure the corners, and ensure that everything is level. A square can help confirm that the corners are at right angles.

Step 4: Attach the Legs – Once the frame is complete, attach the legs to each corner for support. You can either use 2x4s or 4x4s, depending on how sturdy you want your workbench to be.

Step 5: Install the Top – Now, place the cut plywood on top of the frame. Use wood screws to secure the top to the frame, ensuring it is stable and secure.

Step 6: Add Storage – If your workbench design includes shelves or drawers, now is the time to install them. Use additional pieces of plywood or wood to create storage solutions beneath or beside your workbench.

Step 7: Finish Your Bench – Sand any rough edges to ensure safety and apply a finishing coat, like polyurethane, to protect the wood from spills and wear.

Step 8: Test Its Stability – Finally, ensure your workbench is stable by applying pressure. Make sure everything is secure before using it for your projects.

Design ideas to customize your workbench

Customizing your workbench not only enhances its functionality but also allows you to showcase your personal style. Here are some creative design ideas to consider.

Add a Durable Surface: Choose a surface material that fits your needs. For a workbench that sees heavy use, consider adding a removable plywood top to your workbench for easy replacement or reinforcing the surface with a layer of plastic laminate for added durability.

Incorporate Built-in Storage: Maximize space by including drawers and shelves beneath the work surface. Building a small cabinet or installing pegboards can help keep tools organized and within reach.

Install a Vise: Attach a bench vise securely to one corner of your workbench. This tool is invaluable for holding materials in place while you work, making tasks like cutting or sanding more manageable.

Add a Power Strip: Make sure you have electricity at hand. Installing a power strip on or near your workbench allows you to plug in tools without needing to reach far.

Create Adjustable Height: If you often switch between tasks sitting and standing, consider building an adjustable-height workbench. This can be done using a hand-crank or pneumatic lift mechanism.

Use Color and Finish: Personalize your workbench with a fresh coat of paint or a wood stain that matches your workshop theme. This not only enhances aesthetics but can also help in visibility when searching for tools.

Include Task Lighting: Integrating LED lights or clamp lights above your workbench can provide better visibility for detailed work, making projects easier and safer.

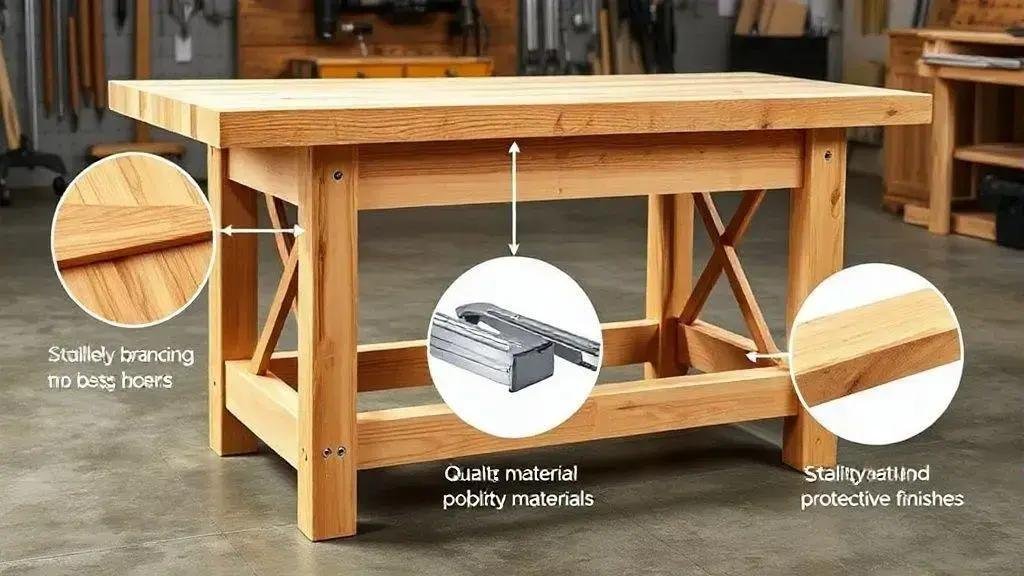

How to ensure stability and durability

Ensuring stability and durability in your workbench is crucial, especially if you plan to use it for heavy-duty tasks. Here are several key points to consider.

Choose Quality Materials: Start with high-quality materials like sturdy hardwoods or thick plywood for the tabletop. This ensures that the surface can withstand pressure and weight without warping.

Reinforce the Frame: Use 2×4 lumber for the frame and add cross-bracing for extra support. This helps distribute weight evenly and prevents the workbench from wobbling during use.

Secure Connections: Use wood glue in addition to screws for stronger joints. Applying glue adds extra holding power, ensuring all parts stay connected properly over time.

Level Your Workbench: Make sure your workbench is perfectly level. Use a level tool while installing the legs and adjust them as needed to prevent any tilt, which could affect stability.

Consider Weight Capacity: Be mindful of the weight capacity you expect your workbench to handle. Overloading can lead to structural failures, so choose materials and design features that accommodate your needs.

Regular Maintenance: Keep your workbench in good condition by regularly inspecting it for signs of wear or damage. Tighten screws and replace any worn-out components promptly to maintain its integrity.

Finishing Touches: Apply a protective finish to the wood surface, such as varnish or polyurethane. This protects against spills and enhances durability, ensuring that your workbench stands the test of time.

Finishing touches for a professional look

Adding the finishing touches to your workbench can elevate its appearance and functionality. Here are some tips to achieve a professional look.

Sand the Surface: Start by thoroughly sanding the workbench top with progressively finer grits of sandpaper. This process removes rough spots and prepares the surface for finishing.

Apply a Protective Finish: Choose a good-quality varnish or polyurethane to protect the wood. This not only enhances the appearance but also guards against spills and wear. Apply multiple coats for added durability.

Use Edging Strips: Consider adding edging strips around the surface of your workbench. This can provide a polished look and prevent splintering.

Install Handle Pulls: If your workbench has drawers or compartments, installing attractive handle pulls can personalize the look while making access easier.

Label Storage: For a neat appearance, add labels to drawers and shelves. This keeps your workspace organized, assists in finding the right tools quickly, and gives a professional vibe.

Customize with Color: If you’re feeling creative, paint parts of your workbench in a complementary color. This can enhance your workspace and make it more inviting.

Incorporate Lighting: Adding task lighting is not only functional but can also highlight the beauty of your workbench. Consider using LED strips around the edges or a stylish lamp on the surface.

Maintaining your workbench for longevity

To ensure the longevity of your workbench, regular maintenance is essential. Follow these guidelines to keep your workbench in top shape.

Clean the Surface: Always clean your workbench after use. Wipe away dust, sawdust, and any spills promptly to prevent damage. A simple damp cloth should suffice for routine cleaning.

Inspect for Damage: Regularly check your workbench for any signs of wear or damage. Look for cracks, warping, or loose screws. Addressing minor issues early can prevent bigger problems later.

Retighten Joints: Over time, screws and bolts may loosen. Make it a habit to retighten these connections periodically to maintain stability and ensure a safe working environment.

Apply Protective Finish: Every few years, consider reapplying a protective finish, such as varnish or polyurethane. This will help protect the wood from moisture, spills, and wear, keeping the surface smooth and durable.

Organize Tools: Keep your tools and materials organized on the workbench. This not only creates a tidy workspace but also reduces the chances of damaging the bench by leaving heavy tools on sensitive areas.

Store Properly: If your workbench is adjustable or collapsible, ensure it is stored correctly when not in use. This prevents stress on the joints and prolongs its lifespan.

Protect from Elements: If your workbench is located in a garage or outdoor space, protect it from extreme temperatures and humidity. Cover it with a tarp when not in use, or move it to a more controlled environment.

In conclusion, building and maintaining your DIY workbench

If you follow these tips, you can create a functional and long-lasting workbench that meets your needs. Choosing the right materials, ensuring stability, and adding personal touches will make your workbench a valuable part of your projects.

Regular maintenance is key to keeping it in great shape. By cleaning your workbench, checking for damage, and applying protective finishes, you will extend its life, making sure it serves you well for years to come.

Your workbench is more than just a surface; it’s a space where creativity and productivity flourish. With the right care, your workbench will become a trusted partner in all your DIY adventures.

FAQ – Frequently Asked Questions about DIY Workbench Construction and Maintenance

What materials should I use for building my workbench?

Using high-quality materials like plywood for the surface and sturdy 2x4s for the frame will ensure durability and strength in your workbench.

How can I ensure my workbench is stable?

To ensure stability, reinforce the frame with cross-bracing and regularly check for loose screws or joints.

What kind of protective finishes should I apply?

Consider applying a layer of varnish or polyurethane to protect the wood from spills, moisture, and wear.

How often should I maintain my workbench?

Regular maintenance should include cleaning after use, inspecting for damage monthly, and reapplying protective finishes every couple of years.

Can I customize my workbench?

Absolutely! You can add storage solutions, install a vise, or paint it to fit your style and needs.

What lighting options are best for a workbench?

LED strip lights or a clamp-on work lamp are great options to provide bright, focused lighting on your workbench.